Chapter 4: THE FACTORIES

While garment and textile manufacturing are no longer booming sectors in the economy, citizens may still catch glimpses of Schuylkill County’s past: old brick factories sit abandoned yet bear their original names in white, painted lettering; new businesses move into buildings that were once factories and now have adopted a connection to the vintage industry; and older generations are reminded of past factory jobs while buying textile goods that are now primarily made in countries overseas. Many of the garment and textile factories of Schuylkill County have closed down or transformed. The industry has become less familiar to younger citizens. As the industry and its factories become increasingly forgotten, citizens have begun to lose the rich history and their awareness of these establishments. The following sections portray histories of a small sampling of the many factories that changed the face of Schuylkill County’s economy during the rise of the garment industry.

Tilt Silk Mill, Pottsville

History of Pennsylvanian Silk

Silk spinning was the first major facet of the textile industry to begin in Pennsylvania and peaked in the 1920s (Stepenoff, 1992). As Frank McNally, manager of a Pennsylvanian company that was once one of the largest silk weavers in the country, puts it, the high concentration of silk companies in northeastern Pennsylvania made a natural transition for the garment industries to settle in the region (McGuigan & Migliore, 2008).

Silk production in the United States took off after tariffs on imported silk were enacted in the 1860s. In 1876, fewer than thirty silk producers operated in Pennsylvania; the number of producers rose by ten times between 1880 and 1925 making Pennsylvania the leading state in the industry by 1914. Similar to the coal industry and the rest of the textile industry, silk spinning was lucrative in northeastern Pennsylvania because it made use of the region’s labor force, many who were children, willing to work at low costs to support their families (Stepenoff, 1992).

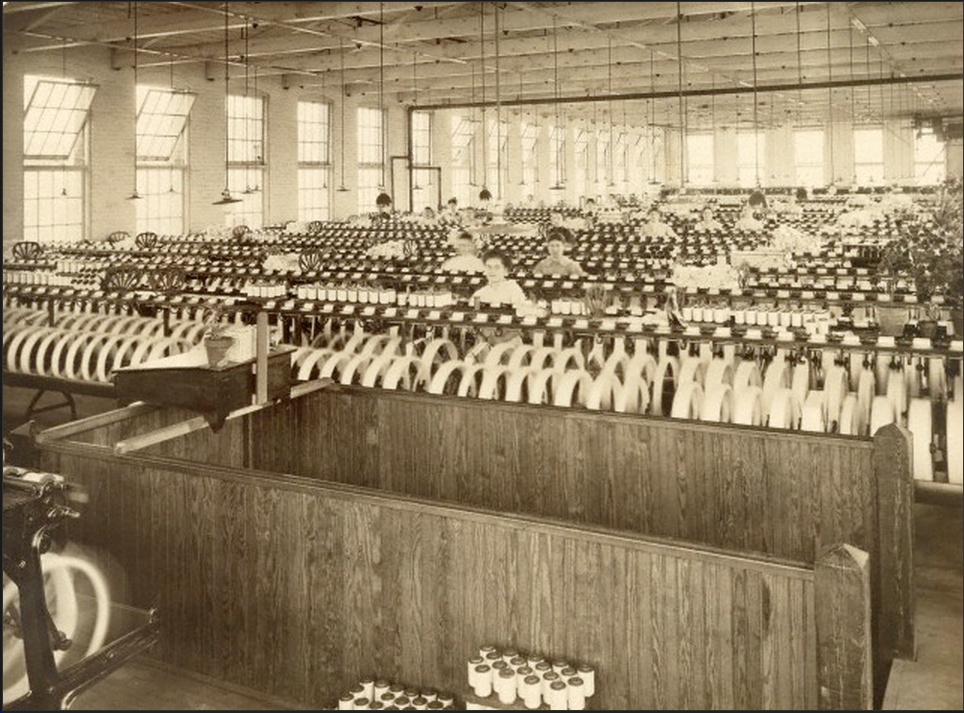

A silk mill in Wilkes Barre (Luzerne County) in 1913. Similar to how Tilt Silk Mill would have looked like (B. Clark, personal communication, March 3, 2015).

History of Tilt Silk Mill

In April of 1887, the board of economic development in Schuylkill County announced plans to attract a mill and shirt factory, which would provide four hundred jobs for local citizens. Yuengling & Son Brewing Company was the project’s first investor buying $5,000 worth of bonds. Soon after, the community raised over $90,000 to recruit the mill (Ward, 1994a).

In May of 1887, after searching throughout the region for a town with low labor cost and impressive waterpower, the leaders of Phoenix Silk Manufacturing Company, including their president Albert Tilt, settled on Pottsville as the location for their new mill (Shriner, 1890; Ward, 1994a). The Tilt Silk Mill, on 12th Street and Laurel Boulevard, took one year to construct, and it began operating on July 17, 1888 (Ward, 1994a). A journalist at New York Times had high hopes for the mill. A day after its opening, the journalist referred to the facility as “the most extensive and completely equipped establishment of the kind in the country, cost $250,000 and will employ 1,000 operatives” (Pytak, 2013).

With another facility located in Allentown in the neighboring Lehigh County, Phoenix Silk Manufacturing used the Tilt Silk Mill facility to throw the raw silk, or, in other words, make the raw silk into a durable yarn for textiles. The silk yarns were then sent to looms in Allentown to create different silk fabrics, such as Jacquard fabric. With the silk fabric, they made dresses, handkerchiefs, scarves, gauze and pongee goods, ribbons, lining and silk braids. Phoenix Silk Manufacturing Company prided itself on their fully American-made products. The Tilt Silk Mill was part of a vertically integrated company protected by tariffs on foreign silk imports (Shriner, 1890).

At its peak, the mill employed 1,500 people. Demand for Tilt’s silk products waned until the mill was forced to shutdown in the 1920s (Ward, 1994a). At this point in time and into the 1930s, as garment production shifted from New York to Pennsylvania, the region was making a transition from textile to apparel manufacture (Smith et al., 2011). One record published in a local newspaper in August of 1932 suggests that the Tilt Silk Mill went idle and planned to reopen in Pottsville. While the new director of the facility issued a statement of determination to secure the mill’s business, proof of its lasting success has not been found (Pottsville, 1932).

After Tilt Silk

The facility that was once Tilt Silk Mill changed hands many times since the 1920s. From 1935 to the 1950s, clothing manufacturer Onyx Blouse Company operated in the same location (Ward, 1994a). In more recent accounts, the property became Edward and Mary D. Keese’s who opened up an auto rental franchise there. (See Figure 4.1.) Parts of the original facility have been removed and modified, but what is left symbolizes 125 years of changes that have occurred since the establishment of Tilt Silk Mill (Pytak, 2013).

4.1 Tilt Silk Facility (Pytak, 2013)

Phillips Van Heusen, Pottsville

Phillips & Jones Co., established in Pottsville, Pennsylvania, was once Schuylkill County’s largest employer (Ward, 1994b). Now known as PVH Corp. and headquartered in Manhattan, it has grown to be the largest shirt company in the world (PVH Corp., 2014).

The Beginning of PVH: 1875-1910s

In 1875, Moses Phillips brought his family from Poland to Pottsville and became the rabbi of the first synagogue in town. While he enjoyed his work, his salary was not sufficient enough to support his large family. Phillips’ wife, Endel, learned how to make flannel shirts, and by 1881, the family was focused on selling shirts door-to-door to neighboring coalminers (How Jews, 2012; Ward, 1994b). The family’s business expanded prompting them to move manufacturing from their home to a small house in Pottsville; then to a larger building in town; and finally, with a push from their son Isaac, to New York City around 1890 (Ward, 1994b).

In 1898, the Phillips moved back to Pottsville and continued to maintain business growth and contribute to the local economy. In the same year, they bought the property of the inoperative Standard Shirt Co. In 1904, they also bought the property of an old gristmill where they built a 25,000-square-foot factory. By this time, the Phillips’ company, now known as M. Phillips & Son, employed 160 people (Ward, 1994b).

Phillips continued to grow business, and in 1907, merged with D. Jones & Son, another shirt company, which had in factories in Johnstown, Lebanon, Millerstown, Myerstown and Schafferstown—towns from 30 to 200 miles west and south of Pottsville. D. Jones & Son also had a factory in Mexico at this time. In 1910, Phillips’s factory in Pottsville was enlarged and became the center of manufacturing for the company (Ward, 1994b).

Those that worked in the Pottsville facility were locals. They would walk to work and start each day at the whistle at 7:30 in the morning. Their tasks were to cut out the shirt pieces and send the sleeves, collars, and cuffs out to specialty factories to manufacture. The pieces would be returned to Pottsville where workers completed the final assembly and finishing (Ward, 1994b).

The World’s Largest Shirt Manufacturer: 1919-1960s

In 1919, after teaming up with Dutch immigrant John Van Heusen, Phillips-Jones became the largest shirt manufacturer in the world (How Jews, 2012; Ward, 1994b). To accommodate business growth, the company bought more property in Pottsville in 1921 and built a new building, which by 1937, was 200,000-square-feet and housed cutting, manufacturing, finishing, laundry, shipping and warehousing departments.

Sales peaked in 1922. By the end of the 1920s, Phillips-Jones was producing over 4 million dress shirts annually in addition to pajamas, underwear, nightshirts, collars, silk cloth and piece goods (Halasz, 2014). In the 1930s and 1940s, further growth led Phillips-Jones to open factories in Barnesboro, PA; Kane, PA; Troy, NY; New York City; Albany, NY; Meridian, MS; Geneva, AL; and Arthurdale, WV (Halasz, 2014; Ward, 1994b). Despite all of these new openings, Pottsville remained the primary facility for manufacturing in the 1940s; however, corporate headquarters were located in New York City (Halasz, 2014).

During World War II, the company received a large order from the Army to manufacture shirts and sent the orders to facilities in Mahanoy City and Minersville—both in Schuylkill County—and also in Barnesboro, PA (Ward, 1994b). Sales boomed during and after the war, and in the 1950s, Phillips-Jones was producing 6.6 million dress shirts per year as well as a variety of other products (Halasz, 2014).

In 1954, Phillips-Jones was manufacturing in 12 plants (Halasz, 2014). By the 1960s, after changing its name to Phillips-Van Heusen, the number of manufacturing establishments grew to 15 and employed 3,970 people in total (Halasz, 2014; Ward, 1994b). The company continued to grow in the 1960s through several acquisitions of smaller companies and through the introduction of new product lines, such as Lady Van Heusen and men’s toiletries (Halasz, 2014).

The Revolutionary Collar

Invented by John Van Heusen Sr. in 1909 and bought by Phillips-Jones Co. in 1919, the Van Heusen collar “revolutionized” the shirt industry (Ward, 1994b). After 9 years of research, Van Heusen developed a new process of fusing cloth into a 3-ply fabric to produce a “soft-folding collar” (See Figure 4.2.) (Ward, 1994b; Van Heusen, 2014). The collar was special because it was the first to be attached to the dress shirt (Halasz, 2014). It was also semi-stiff as opposed to the highly starched, uncomfortable collars of that time (Ward, 1994b; Van Heusen, 2014). Phillips-Jones’ adoption of the Van Heusen collar took business to the next level, and the company was soon listed on the New York Stock Exchange (Van Heusen, 2014).

4.2 The Van Heusen Collar (Van Heusen, 2014)

The End of PVH Manufacturing in Schuylkill County: 1970s to Today

By the 1970s, PVH began to experience losses. The company decided to cut costs by closing down factories in Pennsylvania and moving to regions in the South and in the Caribbean where people were willing to work for lower wages and in worse conditions. Ironically, the viewpoints of the leaders at PVH seemed to have change somewhat in the decades following as they have now focused on human rights for overseas workers, have served on a White House committee to abolish sweatshops, and have given free on-site health care and lunches to their workers in Guatemala (Halasz, 2014). However, despite small pushes towards better working conditions, PVH has continued to shutdown their American manufacturing facilities in preference for lower cost labor. In 1997, three-quarters of PVH’s products were foreign-made. Some manufacturing remains in Alabama and Arkansas, but the majority of it occurs in the Caribbean, Eastern Asia and the Middle East (Halasz, 2014).

American Argo Corp., another large manufacturer of shirts and knit goods in Schuylkill County, moved into one of Phillips-Jones facilities in Pottsville. As of 1992, two of Phillips-Jones Co.’s old facilities in Pottsville have been razed (Ward, 1994b).

J. E. Morgan Knitting Mills, Tamaqua

J.E. Morgan Knitting Mills, a vertically integrated manufacturer of thermal undergarments and baby blankets, was once the largest employer in Schuylkill County and the world’s leader in thermal underwear production, controlling 90% of the world’s supply (Interviewee who worked in product development and costing; Serfass, 2013a). According to a PBS special on Tamaqua, entitled “Winners and Losers,” the mills were “the last of twenty-five textile mills that sustained the community after the demise of the coal industry” (Public Affairs Television, 2003). Morgan Knitting Mills was a conglomerate of four plants in Schuylkill County and others scattered from Pennsylvania to Virginia and Honduras. They produced products for the brands of Hanes, Duofold and Morgan and changed ownership twice before shutting down in Schuylkill County in 2009 (Serfass, 2013a).

The Growth of Morgan Knitting Mills

John E. Morgan founded the company in 1945 in the heart of Tamaqua. With the help of his wife, Anna Hoban, Morgan’s company started as a small sewing factory. In 1954, the company became incorporated and moved to a larger building right outside of Tamaqua in Hometown. While Hometown remained company headquarters, Morgan Knitting Mills expanded, establishing plants in nearby towns within Schuylkill County: Tower City and Valley View and, also in Pennsylvania: Williamstown of Dauphin County and Gilbertsville of Montgomery County. A little further north, Morgan’s also had a plant in Illion, NY and offices in the Empire State Building in New York City (Serfass, 2013a). As business expanded, Morgan’s also established plants in the south in New Market, VA and Mount Jackson, VA (Serfass, 2013a).

Before the 1970s, Atlas Powder Company, a producer of mining explosives, was the largest employer in Schuylkill County with peak employment at 1,300 people. In the 1990s, ICI Americas, Inc. purchased Atlas and sold off most of its manufacturing operations, which led to a decline of employment within the company. By the mid-1990s, Atlas manufacturing had left the county completely (Atlas, 2005). During Atlas Powder Company’s decline from the 1970s to the 1990s, J.E. Morgan Knitting Mills became overtook the position of top employer of the county, switching the county’s focus in its manufacturing sector from mining products to apparel products (Serfass, 2013a).

At the peak of business, Morgan Mills employed approximately 2,000 workers, produced over 42 million thermal knit products annually, and had over $45 million in sales in one year (Serfass, 2013a).

The Morgan Patent

In 1957, the Morgans were granted patent rights to a knitting method designed by Morgan’s wife, which involved the combination of the waffle stitch and the circular knitting machine (See Figure 4.2.). The innovation contributed to a great deal of Morgan Mills’ growth and success in the thermal underwear market (Serfass, 2013a).

The waffle stitch knit fabric, which is still used today, is lightweight, warm and became a great substitute for wool. This fabric, shown in the following Figure 4.3, creates warmth by entrapping air within each square-shaped cell; when on the body, the air that is trapped is body heat, and the fabric becomes an insulator (Jones, 1966). Besides being warm and lightweight, waffle fabric is also breathable, absorbent, durable and flexible (Cao, 2011) making it an ideal fabric for thermal underwear.

4.3 The Waffle Knit (J.E. Morgan, 2012)

Before the Morgan patent, other manufacturers produced fabric with similar properties to Morgan’s waffle knit, however, only by warp knitting methods. Morgan’s fabric differed because rather than producing a warp knit, Morgan made waffle knit fabric with a circular knitting machine; the end product was in a cylindrical form rather than a single, flat layer of fabric (Jones, 1966). The combination of the waffle knit properties and the circular knitting method was advantageous because Morgan’s mills could make sleeves, bodices, pants and other cylindrical shapes used in underwear more efficiently; the circular knitting process cut production time and fabric waste (Interviewee that worked in product development and costing).

Special Programs and Benefits

After conducting several interviews of former workers and reviewing articles of the company, J. E. Morgan Knitting Mills proves to have integrated true corporate social responsibility throughout its existence. John Morgan went above and beyond the traditional corporate role of an owner, and even after he left the business, Morgan Knitting Mills continued to treat its employees well and provided them with great benefits despite the absence of a union.

John Morgan donated millions of dollars to the town of Tamaqua and to hospitals, churches and colleges in the area; these included Tamaqua Borough, the Tamaqua Salvation Army, the Lehigh Valley Cancer Clinic, Coaldale Miners Memorial Hospital, Gnaden Huetten Hospital, Saint Jerome’s Church in Tamaqua, Marian High School, Penn State University, Delaware Valley College, the Tamaqua Public Library and the Bungalow—Tamaqua’s public pool and recreation center. John Morgan was also passionate about antique cars and motorcycles and shared his own collection to the community by establishing the JEM Classic Car Museum in 1985 (Serfass, 2013a).

Besides fair wages, Morgan Knitting Mills implemented several programs targeted to benefit its workers. In the early 2000s, it exercised the Innovation and Savings Plan initiative, in which workers suggested cost-saving ideas and received cash bonuses for ideas that the company used. In 2002, employees’ ideas saved the company $750,000, and Morgan’s celebrated by suspending work for a day and hosting a barbeque with games and prizes (Serfass, 2013a).

One interviewee who worked at J. E. Morgan’s described the mill’s exceptional cafeteria:

One main thing that I always think about was Mr. Morgan, when he built that plant in ‘69, he provided a cafeteria for all of the workers. He had a cafeteria staff. He had a lady that ran it that planned the menus. He had a lady that made the meals. And that was everything from soup and a pork sandwich to a platter. Every Friday, we had baked haddock and macaroni and cheese and stewed tomatoes. Right down to bread and butter. You could get salads, there were all kinds of desserts, Jell-O, fruit cups, french fries, hamburgers and hotdogs everyday. That was one thing that I really missed when they closed down.

Additional benefits that J. E. Morgan Knitting Mills provided to its workers and the community included a company store in Tamaqua that sold discounted, discontinued merchandise. They also had company picnics and sent products to troops overseas (Interviewees that worked for J.E. Morgan’s).

New Ownership and the End of Morgan’s in Schuylkill County

In 1984, John Morgan sold his company to the Scotland-based firm of Dawson International, PLC. Morgan’s health was declining at this time though he did remain on the board of directors. In 1999, the firm was sold again to Sara Lee Corporation, and two years later, John Morgan died at the age of 89. This marked a turning point for the company. Like many other manufacturing companies at that time, Morgan Knitting Mills began moving production out of the United States to overseas countries— mainly to Honduras and China (Interviewee who worked in product development and costing; Serfass, 2013a). Tasks within the remaining factories in Schuylkill County also became more computerized (Interviewee who worked in product development and costing). The combination of effects as well as the increased pressures of international competition led to a decrease in Morgan’s employment in the county.

The 1990s were the beginning of the end for Morgan Knitting Mills. In 1999, the company laid off 300 workers (Parker, 1999), and in November of 2002, Sara Lee announced the plan to phase production out of Tamaqua, which would end the jobs for the remaining 460 workers (Serfass, 2013b). As the company continued to wane into the 2000s, it also liquidated Morgan’s collection of antique vehicles in 2003 (Serfass, 2013a). Employment continued to decrease until the Morgan Mills officially shut down in 2009 harshly affecting the lives of local citizens and the economy (Serfass, 2013b).

While the mills no longer exist, John Morgan’s philanthropist spirit lives on. Morgan’s name is connected to the community’s hope in adapting to new industries. Lehigh Carbon Community College has a center for this purpose called John and Dorothy Morgan Center for Higher Education. The John E. Morgan Charitable Foundation, Inc. is another example of promoting higher education and has donated $4.75 million to the cause in Tamaqua. In addition, the TASD-LCCC-Morgan scholarship program provides two years of free college tuition to students graduating from Tamaqua Area High School (Serfass, 2013c).